Part 1

It’s mid-November, and the snow is flying heavily here in northern Michigan. Many are in the woods chasing deer, following the firearms season opener just a few days ago. Coupled with the cold windy weather, this means that it’s time for most anglers to mothball their boat and store it for the winter.

Here at Wolfe Outfitters, and those of us with Sport Fish Michigan that guide the Lake Michigan tributary rivers for steelhead, we will keep our boats in service all winter long, provided we have running water! Last winter, even rivers like the Big Manistee, Muskegon, and the Grand River froze enough that we were forced to reschedule many trips due to unfishable, icy conditions.

For those that will put their boats away for the winter season, there are a few things that are advisable to do to help ensure a smooth and painless experience when pulling the boat out for the first time next spring.

Trailer

Our trailers are often an overlooked part of our boat package, but yet they play a crucial role. After all, we rely on our trailers to carry our precious boats to and from the lake or river, dunking it in the water each time. This tough kind of wear and tear can be brutal on trailers, and things like wiring, lights, brakes, wheel bearings, etc. can all suffer without routine maintenance. Now is a great time to service your trailer.

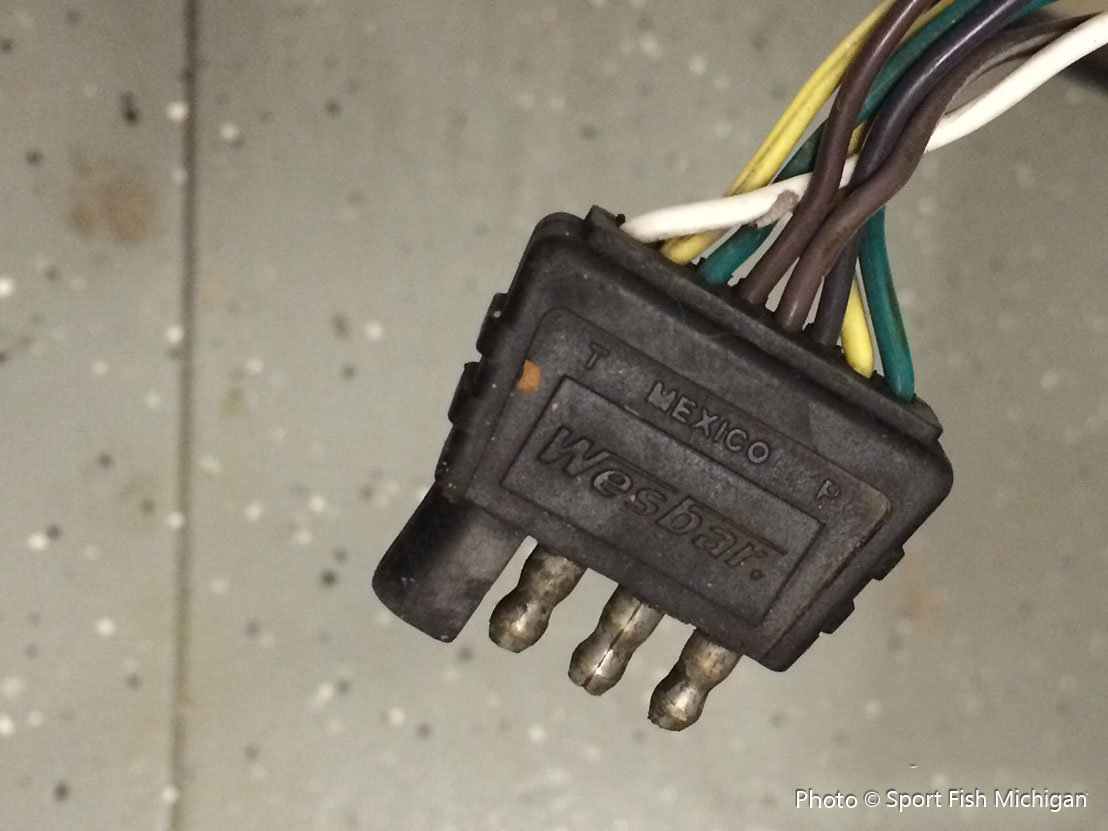

I check over the trailer wiring, looking for kinks or breaks in the lines. I also look over the lights to ensure that they are working properly. Trailer lights are not only a safety concern if they don’t work properly, they are also a legal requirement in most states. Another simple thing to check that often causes trouble is the wiring harness coupler that plugs into the vehicle power to connect the lights and brakes. This simple coupler can absolutely wreak havoc when the pins are slightly bent or have corrosion on them.

Proper tire pressure is essential, not only for gas mileage when towing the trailer, but also for helping to prevent blowouts and unnecessary wear and tear to the treads.

The wheel bearings are another too-often overlooked part of a trailer. Many blowouts on the road are actually a result of bearings that are worn out. Properly lubricating wheel bearings will help keep you on the road trouble-free, but good preventative maintenance also includes replacing the bearings. When to replace trailer bearings is really a matter of how much use they get. Guides that tow boats on a daily basis, like many of our Sport Fish Michigan and Wolfe Outfitters Guides, will have to replace wheel bearings much more frequently than those that tow their boats only a few times a season. New-style bearings like oil-bath hubs or the new gel-style make bearing maintenance almost a no-brainer. Compared to the older and much more common grease-style bearings, these newer technologies keep maintenance to a minimum. For trailers that have the more common grease-style bearings, a simple grease gun will do the trick. Regularly adding a bit of grease will go a long way towards longevity. One telltale to look for when determining if bearings should be replaced is the presence of water. If water gets pushed out of the bearings when grease is added with a grease gun, it could be a sign that the trailer bearings should be replaced soon, if not immediately. Water in the bearings means that the watertight seal has been broken. When the seal breaks, water gets inside the bearings, where it will not only break down the bearing grease, it can also rust the bearings themselves, or freeze in winter temperatures. A little bit of water under the dust cap isn’t a huge deal and can be drained out. But water in the bearings is a big deal, and taking care of this issue now can mean no roadside hassles later.

Another thing that is crucial for those that have brakes on their trailers is to check them for wear and tear. Unless squealing or squeaking brakes have already been detected, checking the life of your trailer brakes is best done by a professional. Throughout the season, trailers with brakes should be checked to make sure their brake fluid level is topped off. Unless there is a leak, this is usually a once a season task.

One more thing to check on a trailer is the tread on the wheels themselves. Make sure that there is enough tread on the trailers to safely transport your boat to and from the water. It’s advisable to carry a spare tire for your trailer and the appropriate tools to change a tire, should there be a flat while out on the road. I always carry a full wheel and tire so that I can make the change and keep going without having to worry about replacing a spare that may not be a match for the trailer tires.

Keeping our trailers going is a big part of a fun day on the water. With some simple maintenance and preventative measures, we can help to ensure that we make it to and from the water without issue. Catching fish is hard enough as it is, without having to deal with a trailer breakdown on the road.